Introduction

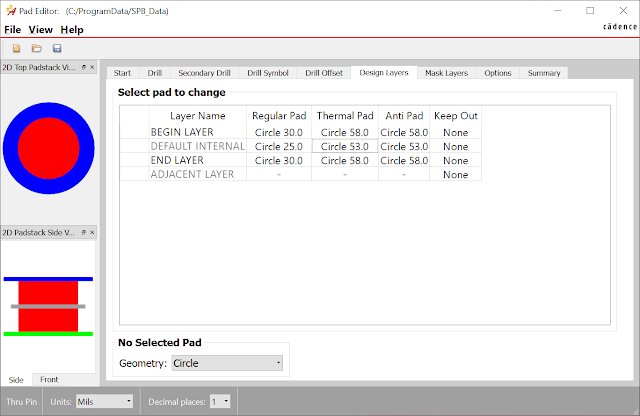

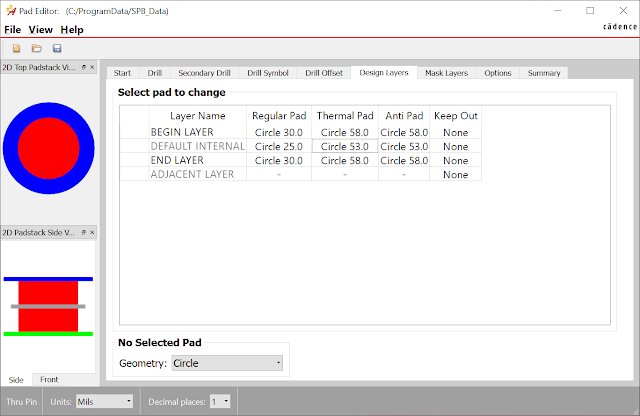

A padstack is a design for the exposed copper surface area for each hole or pad on the board where the component is mounted and soldered (see example, Figure 1). You may need to create a custom padstack when creating custom parts to ensure that the pad and hole are big enough to be reliable. This tutorial describes the manual creation of custom padstacks using the Pad Designer application.

The example below is for a simple round pad. You should look up the dimensions for your own parts.

|

| Figure 1: Padstack examples for through-hole and surface mount devies |

1. Search the Datasheet for the Footprint Specifications

In order to build a custom padstack, you first need to find the footprint (sometimes called "land pattern" specifications in the datasheet for the component.

2. Create a Custom Electrical Padstack

5. Define the Top and bottom layer inner, outer, and thermal geometry. Since Peralta uses two-layer boards, geometry other than begin and end layers will be ignored.

The layers tab provides options for editing individual layers or the entire PCB. You can click on layers and make changes via the Regular Pad, Thermal Relief, and Anti Pad boxes described below.

The default layers for a padstack are:

The layers tab provides options for editing individual layers or the entire PCB. You can click on layers and make changes via the Regular Pad, Thermal Relief, and Anti Pad boxes described below.

The default layers for a padstack are:

- BEGIN LAYER - top copper layer of the PCB

- DEFAULT INTERNAL - inner layers of the PCB (our PCB mill is limited to 2 layers)

- END LAYER - bottom copper layer of the PCB

- SOLDERMASK_TOP - top colored soldermask layer of the PCB

- SOLDERMASK_BOTTOM - bottom colored soldermask layer of the PCB

- PASTEMASK_TOP - top solder paste layer of the PCB (uncommon in class)

- PASTEMASK_BOTTOM - bottom solder paste layer of the PCB (uncommon in class)

- FILMMASK_TOP - top conformal coating layer of the PCB (uncommon in class)

- FILMMASK_BOTTOM - bottom conformal coating layer of the PCB (uncommon in class)

Additional Resources

- Part 19: Designing Pads video from iEngineered

Thank you for allowing me to read it, welcome to the next in a recent article. And thanks for sharing the nice article, keep posting or updating news article.

ReplyDeleteangularjs Training in chennai

angularjs Training in chennai

angularjs-Training in tambaram

angularjs-Training in sholinganallur

angularjs-Training in velachery

It was worth visiting your blog and I have bookmarked your blog. Hope to visit again

ReplyDeleteJava training in Chennai | Java training in Bangalore

Java interview questions and answers | Core Java interview questions and answers

Nice post, thank you so much for sharing this post regarding pcb prototype manufacturing with us.

ReplyDelete